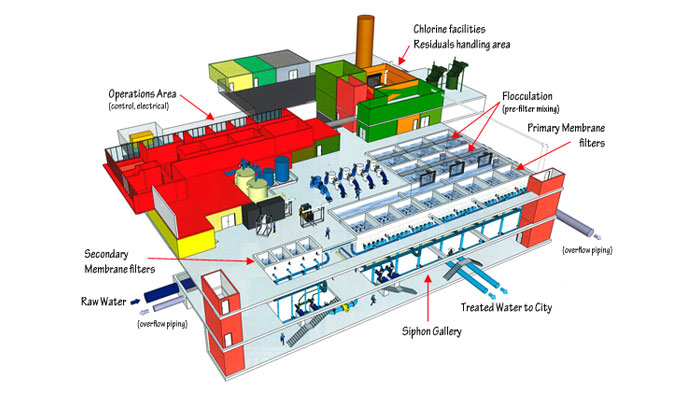

Continental Engineering & Trading Co. we are provider of all kind of waste water treatment Solutions.

Was incorporated in 1992, under the keen business acumen of our venerated CEO, Mr. Aamir Hasan. With his diligent and vigorous efforts the company has achieved new heights.

Was incorporated in 1992, under the keen business acumen of our venerated CEO, Mr. Aamir Hasan. With his diligent and vigorous efforts the company has achieved new heights.

We are ISO 9001:2008 certified company in the field of water and Wastewater from last 10 years;

Also deal in the manufacturing and processing of home water filtration system, domestic water softener and many other water related plants.Moreover we are also counted among the best sewage treatment plant and effluent treatment plant manufacturers in India.