Sewage Treatment Plant (STP)

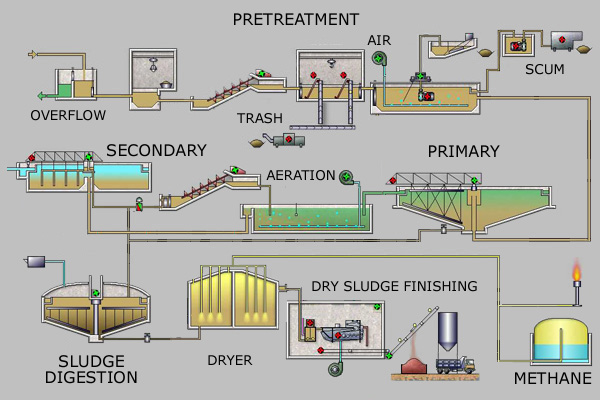

1. Primary Treatment Methods 2. Secondary Treatment Methods 3. Tertiary Treatment Methods Screen chamber Cum Oil & Grease trap helps to remove the floating particles from sewage. Screen with clear openings shall be installed to retain extraneous materials such as plastic bags, waste paper etc. from entering the Aeration tank. The frames will be fitted into the channel grooves. Screen will be physically lifted to the ground level for cleaning operations. A Fat Trap shall also be provided in the chamber where oil will be trapped on the surface of fat trap by providing quiescent condition & providing Laminar flow. The recovered oil will be disposed to permitted hazardous waste disposal site. After passing through the Screen Chamber Cum Oil & Grease Trap, sewage shall be collected in Equalization tank. Raw sewage in Equalization tank is then dosed with the specific cultures. These specific cultures are the result of our extensive research from last three years. These cultures help to degrade the hazardous substances into less toxic or nontoxic substances. The Equalization tank is proposed with diffused aeration system, which is required to supply proper oxygen for our cultures. This aeration also helps equalization & mixing the sewage properly and reduces any chance of dilutions. From Equalization tank, the sewage is pumped to Aeration tank Since the gray water contains high amount of suspended solids we are going for primary settlement prior to biological treatment.

The coagulant chemicals will be dosed to the effluent before entering into the primary tube settler. The tank with hopper bottom contains a tube settle media which enhances the settling process.

In the second stage, FAB REACTOR is also proposed with diffused aeration system. This aeration is induced for generation of bicarbonates by oxidation. This will form heavy flocks and generates H2S, which will escape. The aeration allows helps to make the generated flocks in movement and avoid settling. The continuous addition of nutrients to this tank to maintain F/M ratio and specific cultures to maintain the biological growth. The outlet fromAeration Tank is passed to settling tank for necessary settling of heavy flocks & bicarbonates

The activated biomass developed in theFab reactor all be separate from effluent in Tube Settler. The sludge from Tube Settler & partly from Fab reactoris taken to Centrifuge for solid-liquid separation and the Supernatant passes to chlorine contact tank. The gray water overflowing from the outlet launder of secondary tube settler shall accumulate in the Chlorine contact Tank. Here the supernatant shall be dosed with Sodium Hypo chloride Solution. The dose shall be set based on residual BOD and the presence of colour or odour if any in the sewage. From chlorine contact tank it is passed through Pressure Sand Filter & Activated Carbon Filter. The liquid sludge is dewatered in Centrifuge by solid-liquid separation. The filtrate from Centrifuge is recycled back to bar screen chamber & thick sludge is used as manure. The treated output could be used for various auxiliary applications such as irrigation, gardening, floor washing, machine washing, toilet flushing, firefightingetc., which in turn reduces on cost of intake water.

Sewage Treatment Plant (STP)

![]() Sewage is the mainly liquid waste containing some solids produced by humans which typically consists of washing water, urine, laundry waste and other material which goes down drains and toilets from households and industry.

Sewage is the mainly liquid waste containing some solids produced by humans which typically consists of washing water, urine, laundry waste and other material which goes down drains and toilets from households and industry. ![]() It is one type of wastewater and is a major actual or potential source of pollution, especially in urban areas.

It is one type of wastewater and is a major actual or potential source of pollution, especially in urban areas. Treatment Methods

![]() Sewage describes the processes used to manage and dispose of sewage sludge produced during sewage treatment.

Sewage describes the processes used to manage and dispose of sewage sludge produced during sewage treatment. ![]() Sludge is mostly water with lesser amounts sludge treatment of solid material removed from liquid sewage.

Sludge is mostly water with lesser amounts sludge treatment of solid material removed from liquid sewage. Sewage Treatment methods

A. PRIMARY TREATMENT:

1) SCREEN CHAMBER CUM OIL & GREASE TRAP UNIT:

2) EQUALIZATION TANK:

3) PRIMARY TUBE SETTLER:

SECONDARY TREATMENT:

4) FAB REACTOR:

5) SETTLING TANK:

6) CHLORINE CONTACT TANK:

7) SLUDGE HANDLING SYSTEM: